Material Systems + Pavilion

- Diya Jain, Mahi Dattani

- Jan 6, 2025

- 3 min read

Updated: Jul 20, 2025

Studio Co-ordinator: Dushyant Asher

Diya Jain, Mahi Dattani

The course started with discussions about physical forces and material systems — How the geometry, forces, and different materials have an impact on the functionality of structures.

We started off with an exercise where we explored a variety of operations like friction, diagrid structures, tensegrity, mass and suspension, with an objective to achieve a spread, span, or height of one meter. This compelled us to focus on what kind of materials we would use, depending on the type of forces that would act upon them.

Following this, we analyzed different ways to levitate a piece of paper with the given specifications being the use of skewer sticks, hooks and thread with a maximum of four base points.

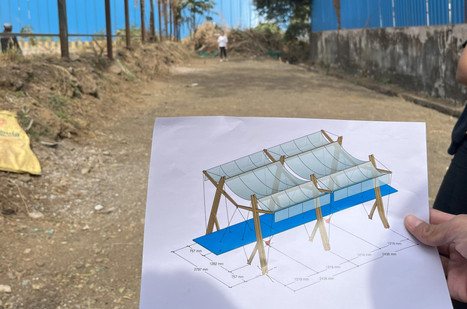

Subsequently, through intuitive explorations and the empirical knowledge derived through iterative processes of design and construction, we arrived at the design of a structure that would be a systematic configuration which suspends a 24-foot long table, creating a space for forty individuals to gather, converse, and feast.

Rather than commencing with the design of a traditional table, the studio began by exploring the forces experienced by the human body, resulting in a system where scale and functionality align with the human body. The conventional notion of a table is reimagined as a dynamic system of forces organized within a precise geometric arrangement. This system, supported by a structural framework, simultaneously functions as the table, the roof, and the primary support mechanism, producing a spatial condition beyond the object’s typical functionality.

The students' engagement extended across multiple facets of the project, including market analysis, cost estimation, material sourcing, component calibration, and assembly. The system explored the materials of wooden members, bison board, steel cables, and other fittings, and foundations of concrete with steel plates connecting the structure to the ground.

Line out and Foundation:

The project began with the line-out group marking the external points with the help of iron nails, tying the line-dori to these points and then tracing the lines with chuna powder, carefully digging out the boxes obtained. Compacting, ramming, soaling and pouring a P.C.C. bed along with curing it was next. Following this was estimating the size of the buckets needed for the foundation as well as welding the metal bars to the steel plates for reinforcement, which was implemented by the foundation group. To keep the buckets in place and construct the foundation, concrete was poured up to the top of the buckets, matching ground level, after which the hollow space was filled back in and the metal plates were welded to the top of the buckets.

Woodwork:

Simultaneously, the woodwork group worked on sourcing and procuring the sal wood, which was preferred due to its strength and durability.

A 1:1 scale drawing of the elevation of the structure was drafted to measure the wooden members. Further, we treated the wood by drafting various sizes of the members, cutting along the drawn edges, waxing it to fill the cracks, sanding, and then ultimately oiling it to make it susceptible to moisture.

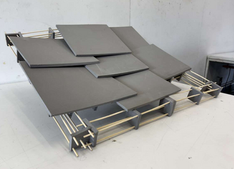

For the table, three 8-foot-long bison board panels were used, connected by attaching a wooden framework to the rear side. The framework incorporated a combination of interlocking and overlapping in its joinery, ensuring that the system functioned as a single unit.

The Assembly:

The crafted wooden members, complete with precision-drilled holes and carefully cut grooves, were now ready to be assembled into a system. Furthermore, referring to the scale drawing, the wooden members were bolted together, carried to the site, aligned, and joined to the metal plates using a combination of spacers, washers, and bolts. About ten people were required to carry a single panel of the bison board. While the bison boards rested on a support beneath, the metal cables were put into place, and the board was lifted to the desired level until the ends of the cables were hooked onto the I-bolts on the bison. The level of the board was then checked and adjusted using a water level, and the same procedure was repeated for the rest of the panels.

The completed space served as a central hub for social interaction, fostering meaningful conversations and connections.

Working on this project taught us how to operate various tools and equipment such as a plum bob, line-dori, favda, metal tamper, vertical drilling machine, sanding machine, allen-key, and many more. Getting hands-on experience on the site not only helped us understand the wear and tear involved in constructing a structure, but also taught us how to collaborate as a class to create a space we can inhabit together.

Comments